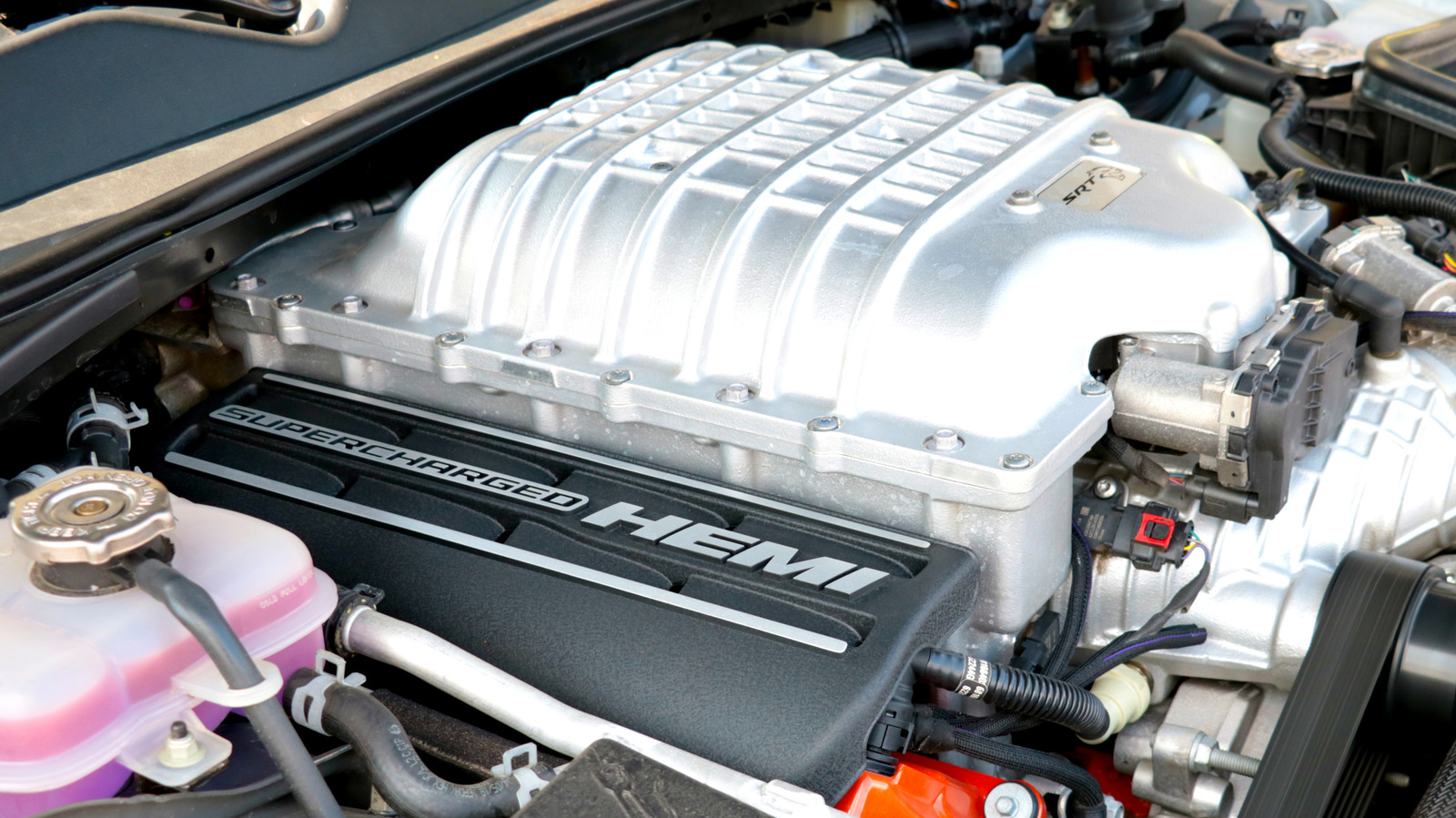

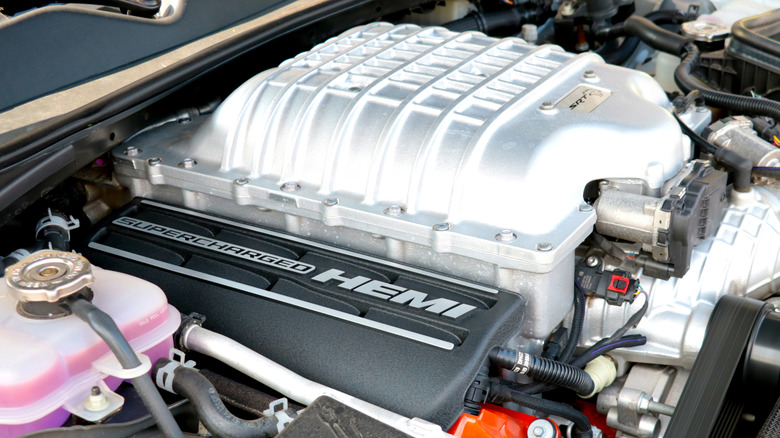

Dmitri Zelenevski/Getty Images

Dmitri Zelenevski/Getty Images

Engines are incredibly complex. They are made out of thousands of different parts, exposed to high temperatures, and have lots of moving parts. This leaves many potential pain points an engine can suffer from. BMW's N47 engine is prone to timing chain issues. Ford's 5.4L V8 is often regarded as the worst engine Ford ever put in a truck due to its spark plugs blowing out the sides of the cylinder heads.

In the case of HEMI engines, they are prone to lifter failure — and here is why that is. According to various technical analyses, many owner reports and repair-shop investigations of HEMI engines, lifter-roller bearing failures seem to primarily be linked to insufficient lubrication. Moreover, these can also be caused by bearing system design flaws that can damage the camshaft lobes, and eventually seize the engine.

Some sources also state lack of general maintenance, metal fatigue over the years, VVT issues with post-2008 engines, and excessive idling as potential contributors to the problem. Ultimately, many things can contribute to lifter issues, and it seems the problem is more nuanced than sometimes believed. Regardless, in order to keep your HEMI as safe from lifter failures as possible, here are a few options worth considering.

Deep dive into potential causes of HEMI lifter failures

Reignited - Cycle and Automotive/YouTube

Reignited - Cycle and Automotive/YouTube

According to Sky, a former Chrysler/Dodge/Jeep technician behind the Reignited – Cycle & Automotive YouTube channel, HEMI lifter failures may stem from how the Multi-Displacement System (MDS) system controls the flow of oil. MDS lifters rely on oil pressure to collapse during cylinder deactivation. However, when MDS isn't active, those lifters can receive reduced lubrication, thus potentially contributing to roller bearing wear. This is why it's important to know whether your HEMI has MDS.

Sky adds that MDS delete plugs often help because they keep the MDS oil passages open, providing constant oil flow to the lifter bores. When we tie this with the fact that earlier HEMI engines used larger roller bearings, it may suggest that lubrication limits and design changes with the roller bearings may have increased the chances of lifter failure for post-2009 engines. Moreover, a technician from Powertrain Products Inc. explains that due to the angle of the lifters in HEMI engines, oil does not inherently flow to the cam.

This ties in with poor lubrication theories as well. Lastly, if we also take into account that, during idling, the MDS system isn't active, the lifter body receives less oil. This can degrade oil pressure and quality and effectively shorten the engine's oil change intervals. If not taken into account, and if you do not revise your oil change intervals to counteract excessive idling, this can accelerate lifter wear and increase the risks of bearing failures.

How to keep your HEMI safe from lifter failures

mark reinstein/Shutterstock

mark reinstein/Shutterstock

First of all, make sure to pay close attention to service intervals, how often you change your oil, proper oil type and viscosity, and engine hours to counter-effect idling. Maintaining proper fluids is one of the essential maintenance tips to extend the life of your HEMI. Many people believe that deleting the MDS system and allowing the oil to flow continuously to the bore is also going to help.

Other solutions such as upgrading the lifter roller needle bearings and improving the camshaft surface will decrease overall material wear. Another idea is to replace MDS lifters with standard lifters, but actually tuning the engine's ECU to keep the MDS lubrication on consistently. The logic behind this method has merit since during the MDS stage, the lifters are at their highest level of lubrication.

You can also replace the lifters with the newer 8784AD NON-MDS lifters from the Hellcat. These come with bigger bearings and can also alleviate some design flaw concerns. So, if you maintain the added lubrication from the MDS stage, you pair it with more durable lifters, and revise service intervals to counter-effect excessive idling, it could lower the chances of experiencing lifter problems. Granted, there are no guarantees the problem will go away, but according to lots of technicians online, it's a likely outcome.